Serious finger injury: procedures during engine maintenance

A member has reported an incident in which an engineer suffered a serious finger injury during planned engine maintenance. The incident occurred alongside during overhaul of a main engine in which the pistons were being replaced.

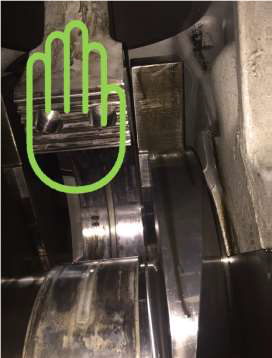

Upon removing one of the pistons, the bottom end bearing cap had been removed and the crankshaft was being turned down to move the crank pin and main bearing shells out of the way of the serrated con rod bottom. The injured person’s right hand was holding the con rod off the crank pin in order not to damage the cylinder liner and crank pin/bottom end bearing shells.

The crank web counter balance was not seen by the injured person as it came around and trapped his little finger between the con rod and crank web counter balance. The crank was immediately turned back and his hand removed from the crank case. He was given first aid treatment on board for a laceration across the width of his right little finger and then immediately sent to local hospital for further treatment.

He returned to the ship the same day having received 7 stiches to the right little finger; the hospital confirmed that there was no other damage.

Our member noted the following:

- Work Planning – the work was fully planned, with Risk Assessment and Toolbox Talks conducted, recorded and on-file;

- PPE – the injured person was wearing full required PPE including mechanics gloves; use of these gloves prevented the injury being far worse;

- Immediate Actions – on-board immediate first aid was applied and subsequent external medical treatment was sought;

- Follow-up Actions – the vessel is updating the existing risk assessment to improve safety emphasis on correct hand placement during the task;

Hand Placement – the injured person had his hand in an unsafe location within the machinery, between the con rod and counter balance; his hand should have been on the con rod itself, with thumb tucked in, to avoid pinch/trapping risks as the counter balance moved.

Feedback from vessel crews

On learning about this incident, crews asked a number of questions about the incident:

- Question: How was the engine barred over? When doing unit liner changes in the past, I always barred over by hand (i.e. very slowly); was this instance hydraulic or pneumatic powered?

- Answer: The engine is barred over using the electric motor powered turning gear. Because of the mounted position of the turning gear it would be unfeasible to rig up any method of “hand” turning gear. The only method of hand turning the electrically-driven turning gear is by means of a machined square on an extension of the electric motor shaft, but the gearing within the system renders this method of turning the shaft impracticable as it would take excessive amounts of time for even the smallest movement of the crankshaft.

- Question: Had the injured person done this type of job before?

- Answer: Yes, the injured person has carried out this job before and is an experienced 3rd Engineer, having recently passed his 2nd Engineer’s CoC.

- Question: Was the Engine Manual being followed?

- Answer: Yes. The engine manual was being followed rigorously during this overhaul as is an absolute requirement for safe operation and future reliability of the engine. There is a dedicated team of competent engineers and fitters assigned to the task, full inspections and calibrations are taking place and a comprehensive report being compiled. Correct re-assembly procedures and torque settings were being followed rigorously and any suspect components replaced. It should be noted that the engine manual provides little specific guidance on handling components during maintenance.

- Question: Was a soft strop used around the con rod, to lift it off the shaft?

- Answer: Not at the time but, since the incident, we have carefully considered different options for supporting the piston and connecting rod whilst turning the crankshaft out, whilst also protecting these components from damage; it is possible to use a substantial wooden lever or a soft strop to avoid placing hands inside.

- Question: What type of engine was it – a V or Inline? In the case of an Inline Engine, once the second last piston is disconnected, the Crankshaft would turn very quickly due to the weight of the last Piston having a turning effect on the crankshaft.

- Answer: V engine. It is recognised that V engines are more difficult to work on, compared to inline engines, due to smaller components for a given power output and restricted space in the crankcase. This vessel has a very large number of cylinder units (40 in total) requiring periodic overhaul which adds time and potential risk to engine work

Members may wish to refer to the following:

Safety Event

Published: 12 April 2017

Download: IMCA SF 08/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.