Near-miss: Unexpected lowering of a suspended load

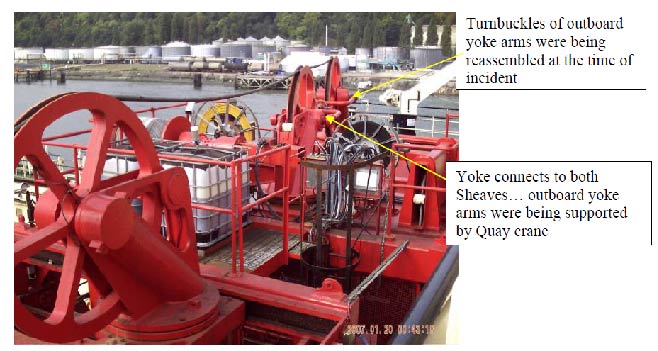

A member has reported an incident in which there was an unexpected lowering of a suspended load during a lifting operation which had the potential to cause significant injury. During maintenance of an ROV winch system, a yoke was being supported in position by a shore crane to allow a specific task to be conducted.

The shore-side crane was provided by the port authority which had sub-contracted it in, along with a rigging team from the port authority. As the end of the working day approached, the crane operator sounded the crane horn to indicate that time was running out. The vessel team agreed with the banksman that all persons would work for an extra thirty minutes to complete the task. However, this agreement was not communicated to the crane driver. Five minutes later the crane operator sounded the horn again as he wished to lower the load. The vessel team and banksman gave little acknowledgement to this. Shortly after this the crane operator lowered the load and shut down the crane as his working day was over.

At this time someone was threading a turnbuckle into the yoke. Due to the weight of the yoke this came out of his grasp prior to the yoke landing and his hands came clear. There were no injuries.

Investigation of the incident revealed the following:

- The crane operator was under the impression that everyone understood his signalling and thought that all persons were clear from the work site;

- The crane operator could not see the work site;

- There was no verbal or radio communication with the crane driver either before (at the toolbox talk) or during the operation;

- There was no lift plan in place for this task, which meant guidance, roles and responsibilities were not well defined. Internal company procedures for lifting were not followed;

- The banksman had no authority from a working hierarchy over the crane operator to agree that he should work an extra thirty minutes. The working hierarchy also created poor team dynamics, as the crane operator was left out of all communications and decisions;

- A string of errors through poor communication almost resulted in a serious injury to personnel working on the winch.

The following actions were suggested:

- Teams conducting lifting operations should ensure that they are familiar with and follow their own company procedures for lifting operations;

- All lifts should have a lift plan – teams involved in lifting are to ensure that lift plans are in place prior to the lift starting;

- All persons involved in lifts should be included in the toolbox talk prior to the start of operations;

- Third-party contractors involved in members’ operations, particularly lifting operations, should be fully briefed beforehand and personnel should be fully aware of the required level of subcontractor supervision;

IMCA guidelines covering this type of operation are as follows:

Safety Event

Published: 10 November 2009

Download: IMCA SF 16/09

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.