Near-miss: Un-noticed expiry and deterioration of carbon dioxide absorbent material

A member has reported a near miss incident in which carbon dioxide absorbent material expired and deteriorated beyond usable condition. This was discovered when a saturation diver reported an acidic taste in his mouth during a lock-out.

Our member’s investigation revealed the following:

- The reclaim tower was found to contain COâ‚‚ absorbent with an acidic odour;

- 27 drums of COâ‚‚ absorbent had recently been received onboard the vessel as part of a field transfer of materials;

- The drums were stored in a shaded area behind the dive complex;

- The crew taking delivery did not check the condition of the material when it arrived, believing that the sender had already checked it prior to delivery;

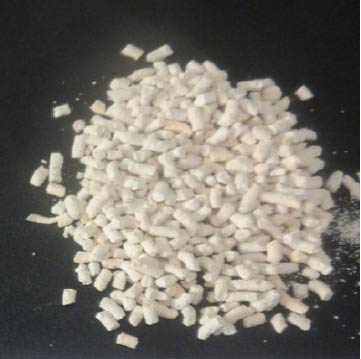

- 23 of the 27 drums of COâ‚‚ absorbent received were found to be discoloured and had an acidic odour;

- Some of the containers did not have labels attached: some were past their ‘use by’ date, and some were still in date;

- The caps of the containers did not seal correctly, exposing the material to salty moisture, extreme heat and high humidity (tropical environmental conditions);

- While there was guidance in company manuals on the quantity of COâ‚‚ absorbent to be used per man per day, there was no company guidance on the correct handling and storage of COâ‚‚ absorbent.

Our member took the following actions:

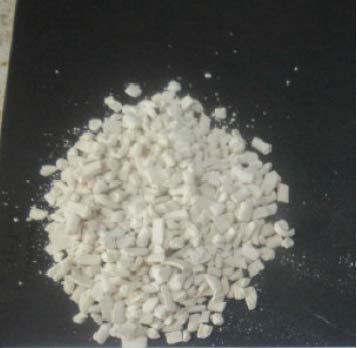

- All COâ‚‚ absorbent material found to be discoloured or expired was immediately removed and replaced with fresh supplies of in-date absorbent material;

- Guidance on the correct handling and storage of COâ‚‚ absorbent, including guidance on delivery inspection, was prepared and issued;

- Guidance on the management of materials that have a shelf life, and are subject to expiry dates, was prepared and issued.

The following lessons were learned:

- Packaging deterioration can occur during the transportation, handling and storage of absorbent material. Once seals have been compromised and moisture enters storage drums, the shelf-life of the material will shorten dramatically. This is particularly so if the material is stored in high-temperature/high-humidity locations;

- Some COâ‚‚ absorbent drums are supplied without expiry dates from vendors. These should not be accepted;

- On receipt from the vendor, expiry dates should be checked to ensure there is a suitable shelf life remaining (recommend a minimum of 1 year);

- Whenever materials subject to shelf-life are transferred from a marine-base to a worksite, or from worksite to worksite, expiry dates should be checked;

- If any transferred goods are due to expire within six months, then the recipients should be specifically informed;

- No items that have exceeded their expiry dates should be used;

- Care should be taken that expiry dates are tracked, and that replacement stock is ordered ahead of expiry;

- Care should be taken to use consumables in order of their expiry (i.e. use the oldest first);

- Any items that exceed their expiry dates must be clearly marked as expired and returned to the appropriate marine base for disposal.

Safety Event

Published: 4 September 2013

Download: IMCA SF 13/13

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.