Near-miss: Divers’ umbilical rupture during routine maintenance

A member has reported a near miss incident in which a diver’s umbilical ruptured. A dive system technician was doing routine pressure testing (following company planned maintenance schedules) on one of the diver’s umbilical. As the umbilical was being brought up to testing pressure, the distinct sound of an air leak was heard. The dive technician stopped further pressurization and went to investigate the air leak.

Before the final test pressure could be reached the umbilical breathing hose ruptured at about 14 Bar pressure.

Our member’s investigation noted the following:

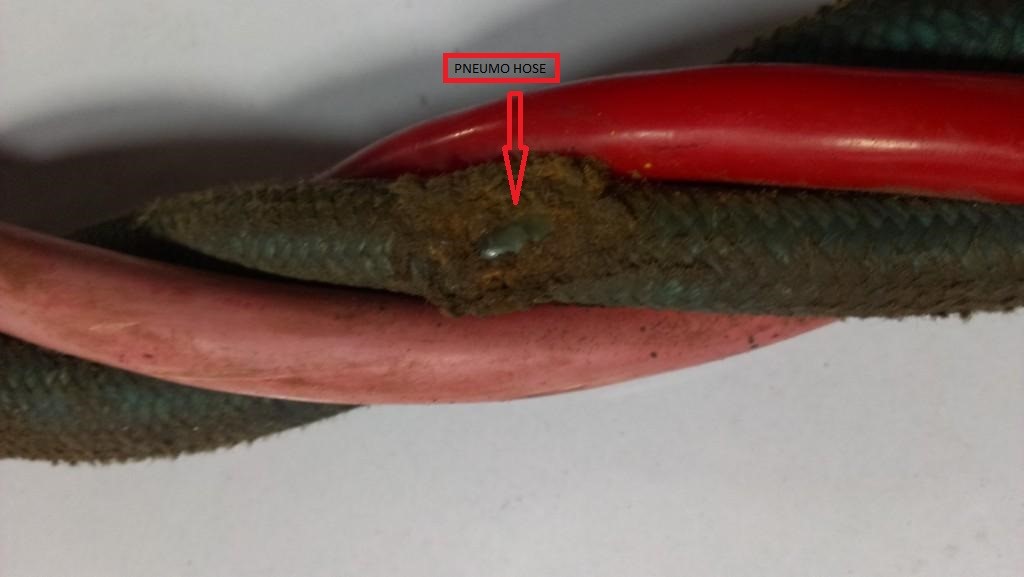

- There was damage to the outer coating of the divers breathing hose at the area of the leak;

- The actual hose had some mechanical damage that may have contributed to the cause of the burst during the pressure test;

- The damage on the breathing hose was 80m from the diver’s end. Since the damage was found 80 meters from the diver’s end, the damage is likely to have occurred somewhere on the diving platform;

- The outer coating of the pneumo hose was damaged at the same location;

- The umbilical was part of a diving system that had just returned from a project and was undergoing a pressure test as per company procedures.

Our member noted that pressure testing should be carried out in a clearly marked designated area, and that all nearby personnel should to be informed when a pressure test is to be carried out. Personnel conducting the test should be using the correct personal protective equipment (PPE). There should be close visual inspection of the umbilical for surface damage before the pressure testing starts – if any area is found to be damaged, the adjacent area should be cordoned off whilst pressure testing.

Our member reiterated the importance of safe umbilical handling and making efforts to keep the diver’s umbilical safe from any damage even on the diving platform at all times.

Members may wish to refer to the following incident (search word: umbilical):

Safety Event

Published: 2 August 2016

Download: IMCA SF 20/16

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.