Lift bag lost when rigging parted

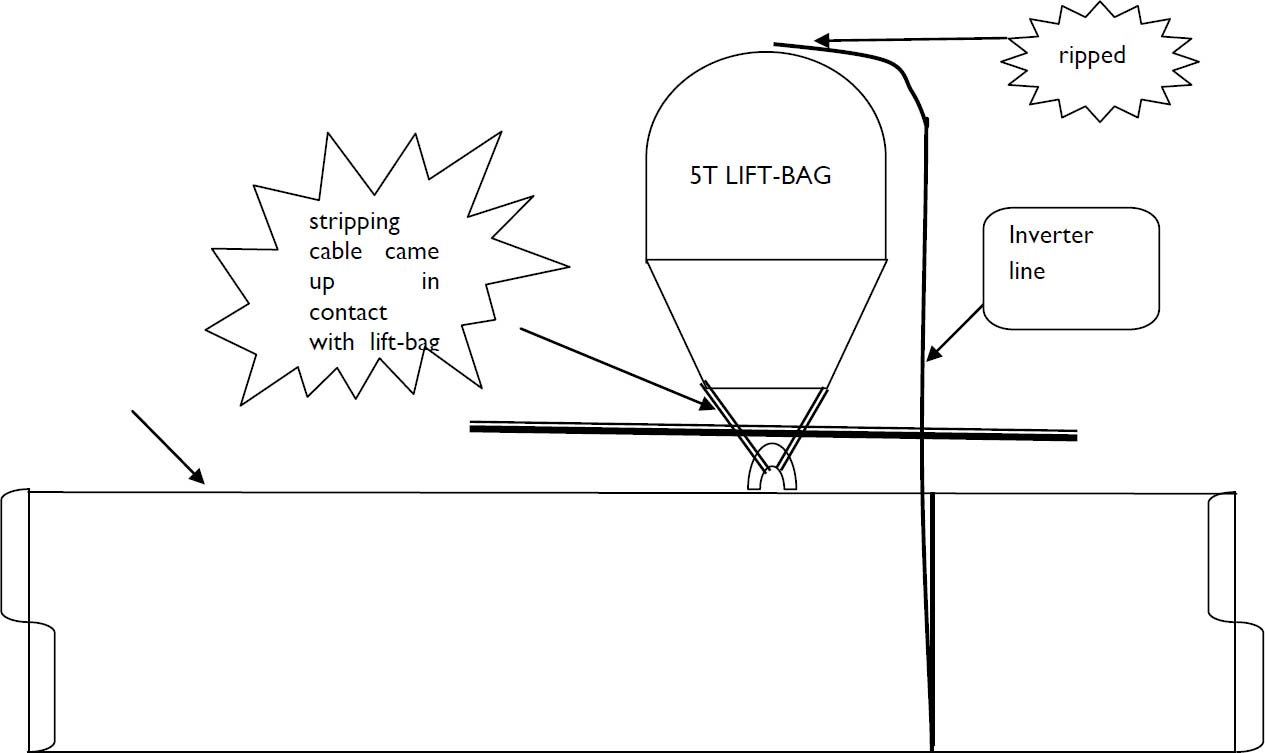

A member has reported an incident in which a lift bag was released to surface upon parting of the rigging attachment point straps. The lift bag was of the open bottomed parachute type. In order to provide additional buoyancy to a pipeline, two five-ton lift bags were secured to the pipe in between pre-installed foam buoys. The buoys were secured by the traditional method of steel straps and bandit clamps. A ‘strip-out’ wire was in place and was run underneath the straps along the length of the pipe to assist removal of the foam buoys once the pipe was in position. The lift bags were rigged and secured to the pipe with appropriately selected and certified rigging. It was determined that the additional ten tons of lift was not sufficient force to cause a loss of control of the pipe. The inverter line was secured to the pipeline and ‘snugged-up’ to avoid a snatch load in the event of failure or an unplanned release of the rigging. Later, upon up-hauling of the strip-out wire to remove the buoys, one of the two bags was found to have parted and was floating on the surface.

Further inspection revealed that the webbing strops of the bag had been cut through when the strip-out wire was pulled at an acute angle across the plane of the pipe relative to the bag. It was also discovered that the inversion line had pulled the attachment points away from the crown of the bag. These strops remained secured to the inverter line which in turn remained attached to the pipeline. It was further determined that the strops at the top of the bags used for attaching the inversion lines were intended for handling purposes only and were not designed as inversion line attachment points.

The following lessons were drawn from the incident:

- Dive supervisor should be informed prior to stripping out the flotation buoys when lift-bags are attached to the pipeline;

- Work plans should be better communicated at toolbox talks and pre-shift meetings;

- Existing safety recommendations regarding the incorrect use of handling strops had not been fully implemented (see item 5 of IMCA Safety Flash 07/07).

The company recommended the following:

- When feasible remove lift bags in advance of potentially conflicting tasks;

- Re-circulate existing safety recommendations, including IMCA Safety Flash 07/07;

- Check identification and marking of dedicated inversion point attachments and lift bags;

- Amend work instructions to include a reference to the inclusion of purpose-built and labelled inversion line attachment points for all future rentals/procurement of this equipment;

- Consider retrofitting inversion attachment points to bags not currently having this feature.

Safety Event

Published: 17 August 2009

Download: IMCA SF 12/09

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.