Explosion of hose-ball valve assembly

A member has reported the following incident, which occurred during an onshore drilling operation. During the operation (run in hole) with a 4½” liner, the crew was instructed to fill up the casing every five joints. To fulfil this task they were using a centrifugal pump. The centrifugal pump and mid pump were controlled by a common device, operated from the driller’s console. During the operation, the driller was in position at the brake and was controlling the SPM and the pressure on the line. The floorman was in charge of the hose filling.

When the operation was completed, the floorman closed the ball valve and asked the roustabout to help him and pick up the filling hose. At that moment, the mud pump activation increased the hose pressure and the ball valve and hose blew, causing an injury to the right hand of the roustabout. The roustabout was visited and the doctor confirmed strong contusion from the elbow to the fingers of his right arm.

The accident investigation pointed out that:

- the filling hose was not a heavy pressure type;

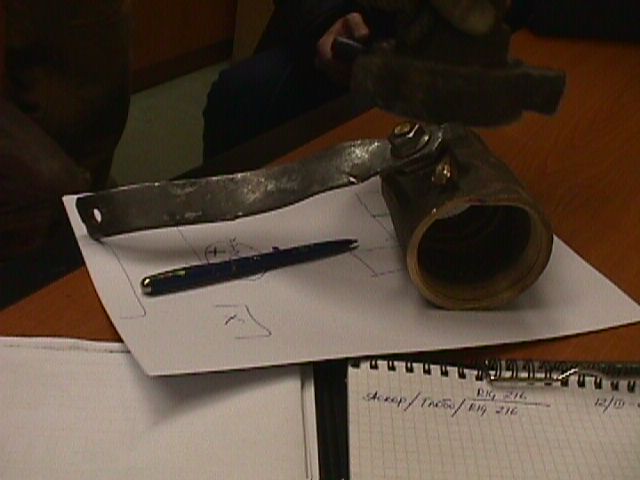

- the centrifugal pump and mud pump were controlled from the driller’s console by the same device (see photo). This system is to be changed to eliminate the reoccurrence;

- there was no relief valve in the circuit;

- the roustabout hadn’t received the appropriate training to carry out duties on the rig floor.

The member concerned has instigated the following corrective action:

- Toolbox meetings and JSA to be implemented and developed in order to ensure proper planning;

- A relief valve will be installed, over pressure shall be safely released and a new control for pumps operating separately from the driller’s console will be installed;

- Ensuring roustabouts will not operate on the rig floor without prior suitable training.

Safety Event

Published: 1 April 2002

Download: IMCA SF 03/02

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.