Stored energy – injury sustained whilst removing metal straps

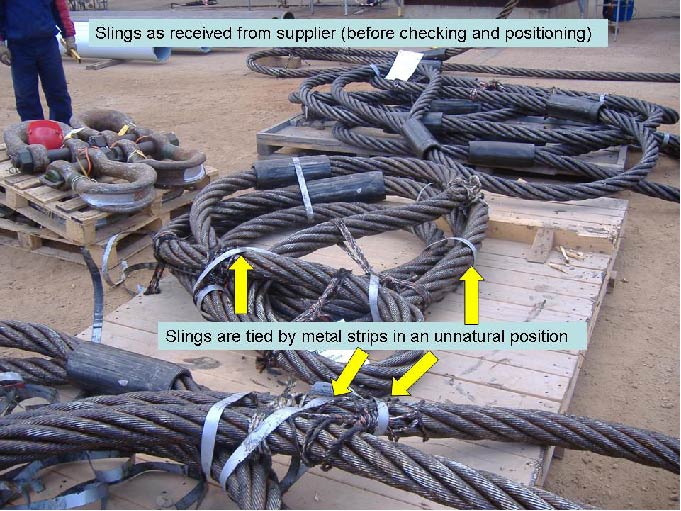

A member has reported an incident in which a crane operator suffered a lost time injury. A team comprising three crane operators, acting as riggers and under the supervision of a foreman, was preparing heavy wire-rope slings for rigging on the spreader bar for a lifting operation. The slings (six in all) were coiled on one large pallet as received from the supplier and had been secured for transportation using metal ‘Band-It’ style straps (see photograph on left below).

The task consisted of unpacking the lifting equipment and checking and positioning all the slings temporarily on the ground. An auxiliary rope for the safe retaining of the slings whilst unpacking them was available on site but this was not used. In order to carry out the job it was necessary to cut and take off the metal straps used by the supplier for transportation/ storage of the grommets.

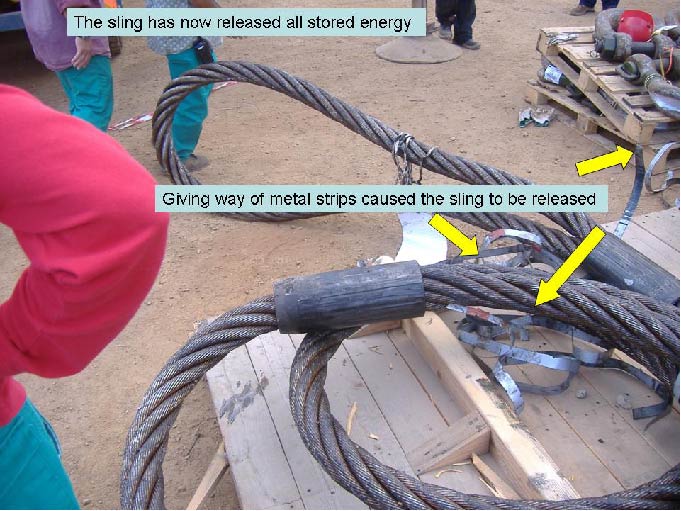

Five slings were unpacked and positioned by the team without any difficulties. During the unpacking and positioning of the sixth sling, as one of the two retaining metal straps was cut, the second strap became over-tensioned and gave way. The sling acted as a spring and moved violently outwards, striking the crew member on the helmet and ankle. Following first aid the crew member was taken to hospital for further examination. The crew member was unable to return to work for 20 days.

The following factors were identified as contributory to the incident:

- High levels of stored energy resulting from extreme compression while coiling/packaging to optimise transportation on one pallet;

- Inadequate pallet, not large enough to handle this kind of package;

- Lack of communication on the part of the supplier of the relevant hazards (stored energy/slings under tension) and inadequate instructions for safe removal of the metal wraps;

- General lack of communication between supplier and user about residual risks related to handling packages of this kind;

- Team did not use available equipment to contain the sling under tension whilst cutting the wraps;

- Risk was not appropriately assessed before the start of the job; no relevant job safety analysis took place.

The following actions were suggested:

- Improve communications between supplier, client and user so that hazards of such packages were fully understood and risks appropriately controlled;

- Supplier of slings to send relevant information and instructions for the safe unpacking of its products;

- Develop procedures for safe unpacking of metal slings;

- Make full use of existing safe systems of work;

- Perform risk assessment and job safety analysis before starting the job.

Members’ attention is also drawn to section 2.1 of Guidance on wire rope integrity management for vessels in the offshore industry – which highlights the hazard posed by stored energy in wire ropes.

Safety Event

Published: 3 December 2008

Download: IMCA SF 17/08

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.