Fatality and serious injuries during heavy lift operation

One man was killed and nine others were injured at a construction site during the lift of a 300 tonne alternator. The lift, using hydraulic jacks and beams, was nearing completion when the equipment collapsed for unknown reasons.

This report has been issued by a company involved as a precaution against similar incidents, following up on the initial report given as item 5 of Safety Flash 02/03 (Fatality and serious injuries during heavy lift operation).

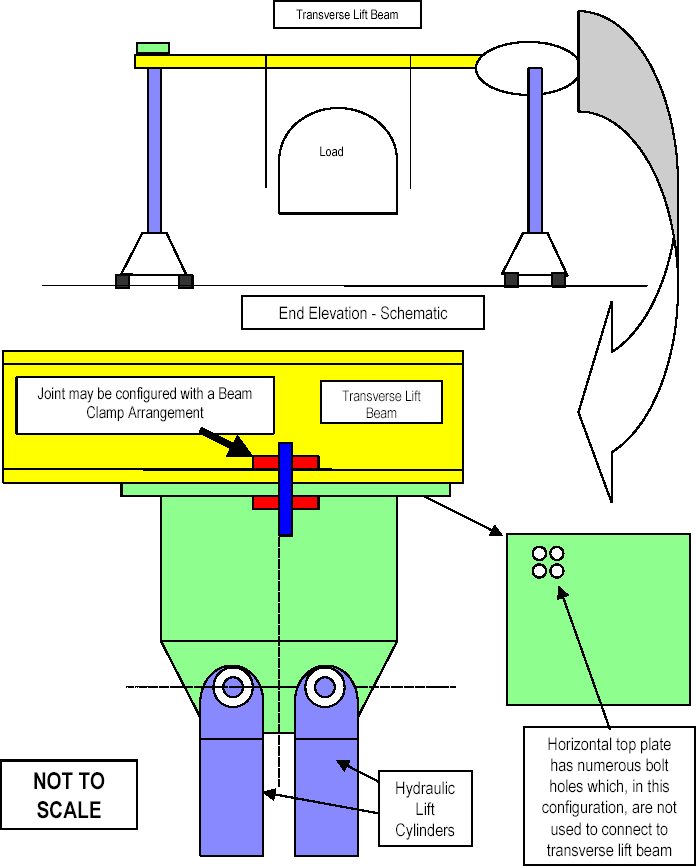

The system may be assembled as shown schematically above in figure 1. In this configuration, the horizontal top plate, which forms part of the connection to the vertical lift cylinders, is connected to the flange on the underside of the transverse lift beam via a ‘beam clamp’ arrangement.

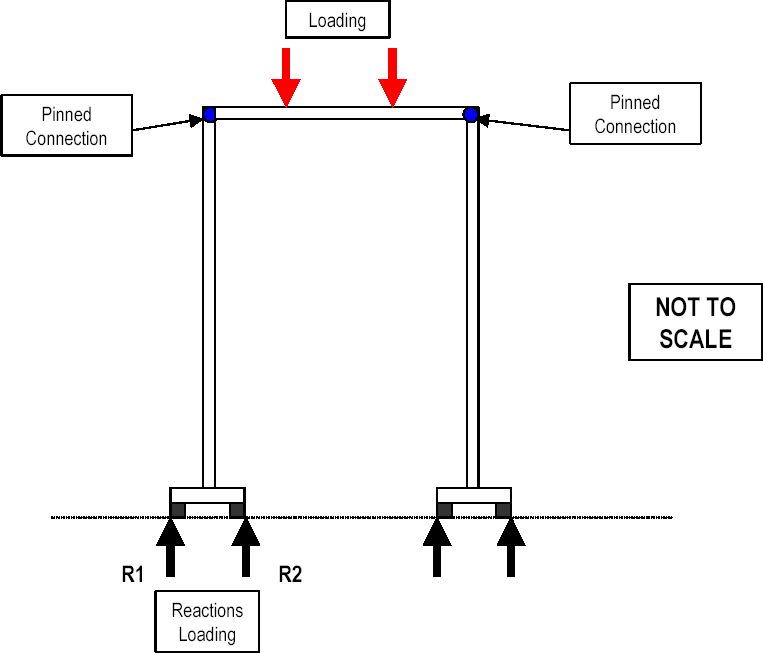

If it is configured in this way, the lifting arrangements may be represented by the structural idealisation shown in figure 2. In this case, the transverse stability of the system is derived from the moment generated by the difference in vertical reactions (at points R1 and R2) between the inner and outer guide rails. However, this may be limited as the supports may have no capacity to resist an uplift or tensile load.

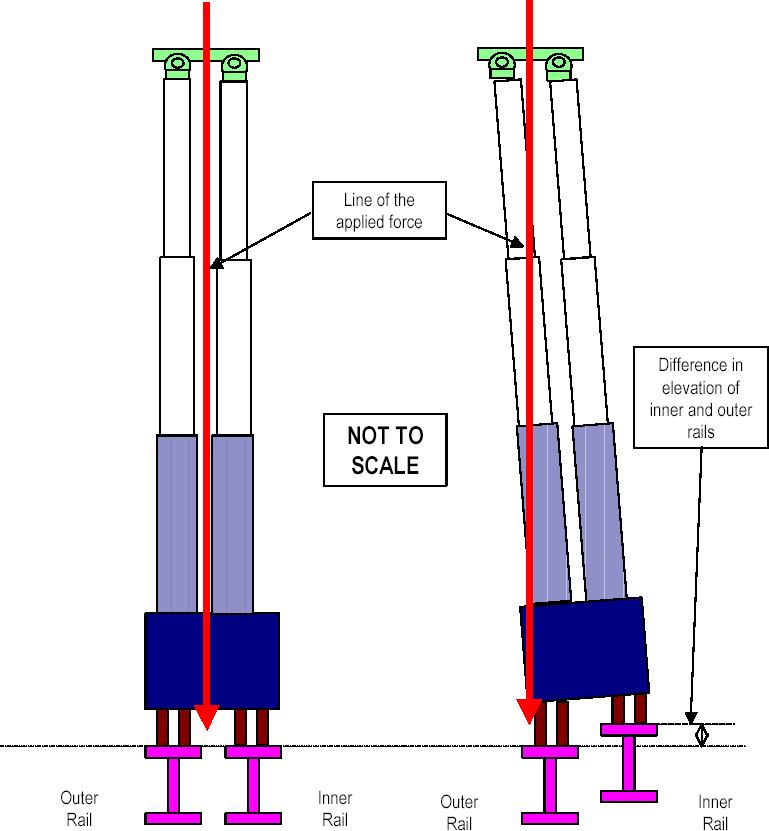

When the inner and outer guide rails are level, the line of action of the force is between the guide rails, as shown in figure 3A. If there are differential levels between the inner and outer guide rails, this may result in the line of action of the force moving outside the base, which in turn may impact the stability of the entire system, as shown in figure 3B.

The company involved has made the following recommendations:

- A suitably qualified and competent person should check the stability of any lifting arrangements which incorporates similar vertical lift systems. This review should address the following issues:

- All possible conditions which may result in a differential deflection between the inner and outer guide rails at the base should be considered and their impact on the overall stability of the system fully evaluated;

- The permissible out-of-level tolerance between the inner and outer guide rails and the permissible tolerance for the vertical alignment of the lift units should be derived by calculation for all stages of the operation;

- All permissible tolerances should be included in the method statement and clearly communicated to all those involved in the operation.

- A system which is capable of monitoring the vertical alignment (in two orthogonal planes) of the hydraulic lift cylinders should be devised and used during the operation.

Safety Event

Published: 1 April 2003

Download: /home/storm/sites/dev-imca-int-com-1/public/wp-content/themes/imca-website-2020/single-safety-events.php on line 55

">

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding safetyreports@imca-int.com to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.